Quality Assessment based on samples

Often, assessment of quality of a process or a product lot is done by verifying samples from such processes or lots.

Processes are accepted as good or lots are certified as acceptable based on what you find in the samples inspected.

Reasons for incorrect assessment of Quality

At times the assessment of Quality based on observed samples can go wrong and an incorrect decision is likely to be made.

Incorrect decisions about quality can be due to the following two reasons:

1. The measurement system used to evaluate the samples can potentially have measurement errors.

2. The samples verified may not be the true representatives of the true Process or Lot Quality.

Types of Errors of assessment

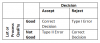

The table below shows the two types of errors that occur in assessment of Quality

![[IMG]](http://www.qualityforumonline.com/forum/index.php?attachments/measurement-errors-png.20/&temp_hash=45a217b418e96428581fa6513c405040)

Containment of Errors of assessment

Probability of committing the Type I error is denoted by the Greek symbol alpha, whereas the probability of committing the Type II error is indicated by the symbol beta. The errors are often colloquially referred to as alpha and beta errors. Both probabilities can be evaluated scientifically.

Measurement errors can be evaluated with the scientific technique of Measurement Systems Analysis. The statistical technique of MSA is able to evaluate the quantum of alpha and beta errors of measurement. It also gives an indication of the probable causes of these errors.

Errors on account of sampling can be scientifically evaluated by doing sample size calculations.

It is seen from the table above that the Type II (Beta) error leads to low quality products getting shipped to customers. Beta error is thus a more serious error.

Design and selection of Measurement systems as well as Design of sampling plans thus need to be driven by considerations of containing the serious beta errors.

Dismiss Notice

You must be a registered member in order to post messages and view/download attached files in this forum.

Click here to register.

Click here to register.

Measurement and Sampling Errors

Errors in Quality assessment and their impact